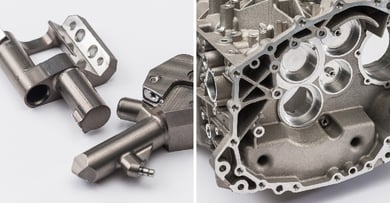

High cost-performance prototype development optimised for mass production

Double-digit percentage cost reductions

We at Tsuzuki Co. have absolute confidence in development and design prototyping for components eventually intended for mass production.

Our work is founded on principles of value engineering, drawing on our abundant experience with mass production and the processing of automobile components and components for construction machinery.

While providing requested functionality and quality, we will actively pursue value engineering-based proposals that achieve stronger, more lightweight, more widely functional products as well as reduced costs during the mass production process.

We boast high standards of safety for transmission components, suspension / undercarriage components, and similar, while also having achieved double-digit percentage cost reductions for component manufacturing requiring high strength and precision.

Professionals specializing in mass production

One of Tsuzuki Co.’s core beliefs: Manufacturing that adheres to the blueprint is only the obvious first step. We believe that our value to society lies in our ability to bring added value to products that exceeds the required specifications.

It is no simple task to improve something while maintaining its current performance. Tsuzuki Co. is able to accomplish such feats only because we are a group of professionals specializing in mass production and processing that has built production lines responsible for 30,000 units of output per month.

How many complex processing steps can we remove?

How will we maintain precision and strength once those steps are removed?

We have amassed tremendous experience in these areas. If you are considering mass production of your product, please come to us and begin consultation for your product starting from the prototyping phase.